Introduction

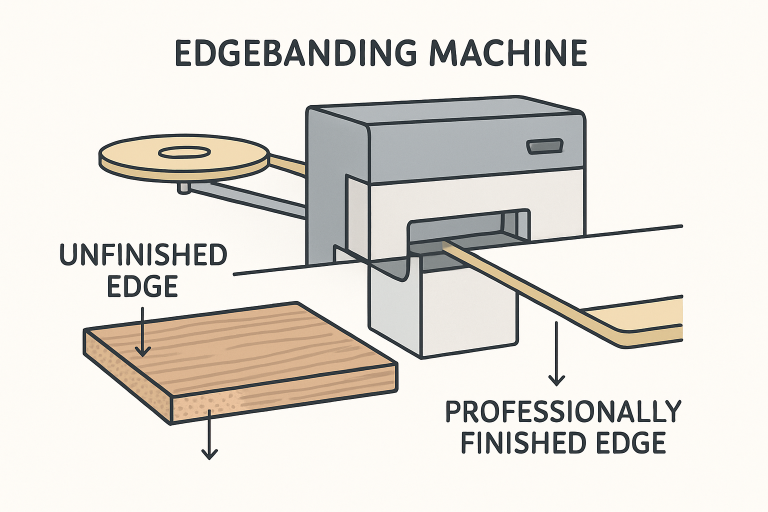

In today’s competitive woodworking industry, standing out means delivering superior finishes that are both aesthetically pleasing and durable. Quality finish is one of the defining factors that separates a professional workshop from a hobbyist’s garage, and the expectations of clients and end-users have grown significantly. One of the most transformative innovations for modern workshops has been edgebanding machines. These sophisticated machines automate the application of edge materials, eliminating inconsistencies and significantly enhancing production efficiency. By adopting this advanced equipment, businesses can ensure their products maintain a high standard, which is essential in building a solid reputation and attracting repeat customers.

Reliable edgebanding ensures that furniture, cabinetry, and millwork not only look professional but last longer under regular use. The crisp, seamless finish achieved using edgebanding machines offers enhanced protection against daily wear and tear, moisture, and impacts, which is especially crucial in high-use areas such as kitchens and office environments. As more woodworkers invest in this equipment, the demand for faster, more precise, and more versatile solutions continues to grow, setting an industry standard for quality and productivity. In the evolving woodworking sector, embracing technology like edgebanders is quickly becoming not just a competitive advantage but a necessity for remaining relevant.

Enhanced Efficiency and Productivity

Traditional manual edge banding is a slow and demanding process, requiring skilled labor to carefully affix and trim edge materials. Workers must take meticulous care to ensure that adhesives are applied evenly and that excess material is trimmed without damaging panels—steps that are both labor-intensive and time-consuming. This can bottleneck production, especially when managing large orders or working under tight deadlines where delays can impact customer relationships and revenue opportunities. Automated edgebanders streamline this crucial step, dramatically increasing throughput while maintaining higher standards of accuracy. Tasks that once consumed hours can now be accomplished in minutes, allowing shops to accept more projects and improve their turnaround time.

By relieving skilled professionals from repetitive tasks, shops can better allocate resources, focusing talent on higher-value work such as custom designs, creative processes, finishing, or personalized client consultations. Increased efficiency not only boosts revenue but bolsters a company’s reputation for reliability and prompt delivery. Greater output and the ability to fulfill orders quickly can secure long-term contracts with builders, architects, and designers, driving business growth far beyond the original equipment investment.

Consistent Quality and Precision

Hand-applied edge material can result in visible seams, glue lines, or uneven finishes—all issues that detract from the perceived quality of a final product and can result in costly callbacks for repairs or adjustments. Inconsistencies in pressure, glue distribution, and trimming can be challenging to control manually, regardless of the worker’s skill level. Edgebanding machines bring a level of consistency that is impossible to replicate with manual efforts. Uniform pressure, temperature, and speed settings ensure that every length of edge is applied flawlessly, resulting in clean lines and seamless joints every single time.

This mechanical precision translates directly to customer satisfaction. Clients can expect the same pristine result whether they order one piece or a hundred, meaning businesses benefit from fewer returns, less rework, and improved word-of-mouth advertising driven by happy clients showcasing their beautifully finished furniture and cabinetry to others. Superior, repeatable quality helps businesses secure their place in a crowded market and becomes a significant selling point when approaching new customers or commercial partners.

Versatility in Material Handling

Modern edgebanders are engineered to apply a wide variety of edging materials, including PVC, ABS, wood veneer, melamine, and even acrylic. This flexibility allows woodworkers to meet an expanding array of client preferences and design trends without needing to invest in multiple machines or limit their customer offering. Whether a client requests a classic wooden finish or a contemporary high-gloss edge, an advanced edgebander can be adjusted to meet the challenge. As explained in Wood Magazine’s guide to edge banding basics, the ability to quickly switch materials and settings enables shops to pivot between projects, broadening their offerings and adapting to the ever-changing needs of the interior design and architecture industries. By exploring creative combinations of materials and finishes, woodworkers can differentiate themselves in the marketplace, attracting homeowners, contractors, and commercial clients alike. This adaptability is key to thriving in an industry driven by customization and personalization.

Cost Savings and Waste Reduction

One of the most practical benefits of edgebanding automation is material conservation. Automated edgebanders are programmed to apply exactly the right amount of adhesive and edging, so they not only minimize leftover scraps and costly mistakes but also optimize usage to extract the most value from every material purchased. This precise application reduces overall consumption and the frequency of reordering supplies. Integrated trimming and buffing features also ensure streamlined workflows, reducing the time and expense associated with manual touch-ups or corrections later in the production process.

Over time, the investment in an edgebander recoups itself via lower labor costs and decreased material waste. Shop owners can quickly justify equipment upgrades based on the long-term return on investment compared to inefficient manual techniques. Reducing waste is also environmentally responsible, helping workshops minimize landfill-bound offcuts and glue containers while supporting sustainable manufacturing practices that many clients now seek out as a differentiating factor.

Integration of Advanced Technology

Contemporary edgebanders utilize digital innovations, including touch-screen controls, programmable logic controllers (PLCs), and Internet of Things (IoT) connectivity. These advancements enable operators to quickly recall settings for different jobs, monitor operational data in real-time, and perform remote troubleshooting. With these capabilities, production lines become more agile, predictive maintenance lowers the risk of downtime, and workflow interruptions are minimized. Digital interfaces also allow less experienced operators to quickly learn and manage machine controls, lowering the barrier to high-quality production.

As manufacturing continues to embrace Industry 4.0, workshops using connected edgebanders can integrate production metrics and maintenance alerts with broader management systems. This early adoption of technology positions woodworking businesses at the forefront of innovation, ensuring long-term competitiveness and sustainability.

Improved Workplace Safety

Manual edgebanding often involves sharp tools, hot adhesives, and repetitive motions—all of which carry injury risks. Operators face cuts from trimmers, burns from glue pots, and long-term strain from repetitive movements, in addition to the hazards posed by dust and fumes. Automated machines help eliminate many of these hazards by enclosing moving parts and reducing hands-on involvement. Well-designed safety features further protect operators, including emergency stops, guards, and warning sensors. This not only creates a safer workplace but also helps shops comply with strict occupational health and safety standards.

Employees enjoy a safer, more comfortable, and less fatiguing work environment, and business owners see fewer injury-related work stoppages, lower insurance premiums, and a more productive team overall. This contributes both to workplace morale and the bottom line, making safety not just an ethical benefit, but a smart financial decision.

Conclusion

Upgrading to an edgebanding machine offers far-reaching advantages for professional woodworking shops. Enhanced efficiency, outstanding consistency, unmatched material flexibility, and durable cost savings are only the beginning. Integrated technology and a safer working environment complete the package, making advanced edgebanding equipment a cornerstone for modern woodworking excellence. It’s also a statement to clients that your business is committed to quality, speed, and innovation.