Industrial adhesives are fundamental to the reliability and performance of numerous manufactured products, silently binding materials across various sectors, including electronics, transportation, and packaging. In today’s manufacturing environments, adhesives are not simply “glues” but perform critical tasks that ensure the safety and longevity of the products we depend on every day. They join materials that would otherwise be difficult or impossible to unite, such as lightweight composites or dissimilar metals, and their influence often extends beyond bonding to include vibration dampening, environmental sealing, and even energy conduction. As market pressures for efficiency, safety, and sustainability intensify, research and development in adhesives is accelerating and reshaping industry standards. New materials, smarter technologies, and sustainable processes are driving this transformation at a pace never before seen. For professionals seeking an adhesive for construction or other demanding applications, understanding the rapidly evolving landscape of adhesive innovation has never been more crucial. The next generation of industrial adhesives is poised to address a wide variety of engineering and environmental concerns, making it essential for designers, engineers, and manufacturers to stay informed about these advancements. Manufacturers demand bonding agents with high strength, flexibility, and minimal environmental impact. Industrial adhesives, including renewable resources and self-healing polymers, meet unique assembly needs and regulatory standards.

Bio-Based Adhesives

Bio-based adhesives are gaining popularity due to their eco-friendly nature and lower reliance on fossil resources. They are being used in packaging, woodworking, and automotive applications due to their strength and durability. Research from reputable sources such as ScienceDaily demonstrates that some bio-based adhesives even surpass the performance of older synthetic products, highlighting their real-world practicality. Additionally, these adhesives often have the added benefit of being compostable or recyclable, allowing for seamless integration into circular economy models and reducing the environmental impact of end-of-life products. Thus, the adoption of bio-based adhesives is not only an ecological imperative but also an opportunity to enhance product performance across various industries.

Smart Adhesives

Emerging smart adhesives integrate responsive technologies directly into bonding materials, vastly expanding the potential uses and reliability of adhesive bonds. These advanced adhesives are engineered with embedded sensors, polymers, or chemical agents that enable them to sense and react in real-time to their environment. For instance, temperature-sensitive adhesives can adjust their tackiness according to operating conditions, allowing for the maintenance of optimal bonds under both hot and cold conditions. Moisture-sensitive options, meanwhile, swell or contract to maintain bond integrity even with fluctuating humidity. Examples of these include self-cleaning adhesives, which minimize buildup on machinery to achieve higher uptime, and reversible adhesives that facilitate the detachment and reuse of components. This smart adaptation enables more efficient repairs, upgrades, or recycling processes, particularly in electronics and automotive assembly lines, where quick and non-destructive disassembly can offer significant cost, time, and sustainability advantages.

High-Performance Adhesives

Industries ranging from aerospace to medical devices now require robust adhesives that can withstand extreme conditions. Thanks to advances in polymer science and molecular engineering, modern high-performance adhesives remain stable at temperatures above 500°F (260°C), and are highly resistant to solvents, oils, and aggressive chemicals. Their resistance to creep, peel, and fatigue has enabled engineers to design a broader range of assemblies that can be safely attempted. For sectors such as aviation, where safety margins are tight and tolerances are minimal, these adhesive formulations allow the design of assemblies that are not only lighter but also display greater resilience in the face of fatigue loads and harsh external environments. Their reliability transforms assembly design by enabling lighter, safer, and more durable structures across high-stress applications, such as jet engine housings and surgical implants. Such formulations are integral to innovative designs where traditional fasteners would fail to perform, making them indispensable to contemporary engineering projects.

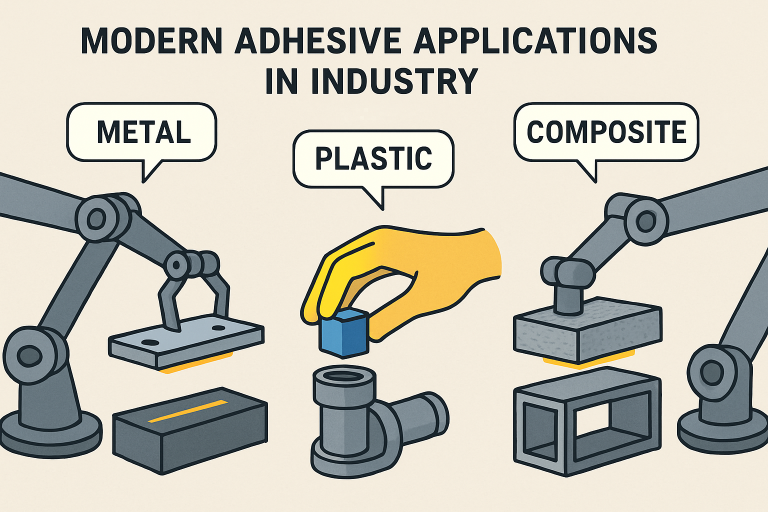

Advanced Manufacturing Techniques

Innovative production techniques are optimizing both the development and application of adhesives, supporting a new era of precision and efficiency. Automation and robotics have enabled scalable, precision-based adhesive dispensing, reducing waste and ensuring precisely controlled curing processes. The adoption of smart applicators and real-time inspection tools ensures that the right amount of adhesive is applied exactly where needed, reducing errors, improving product consistency, and lowering costs for large-scale manufacturers. Meanwhile, 3D printing enables manufacturers to create custom adhesive forms or deliver tailored compositions for unique joint requirements, thereby broadening the scope of feasible applications that cannot be addressed with off-the-shelf solutions.

Nanotechnology further advances the field, creating adhesives with micro-engineered features that enhance strength and tailor material responses, laying the foundation for next-level product engineering. Through the manipulation of particles at the molecular level, manufacturers can imbue adhesives with functionalities such as enhanced conductivity, antimicrobial properties, or directional curing characteristics, catalyzing the development of new device architectures and more innovative products. All these manufacturing advances empower producers to remain agile, responsive, and innovative in highly competitive markets.

Collaborative Innovations

Success in the adhesives industry is not achieved in isolation. Instead, deep collaboration between manufacturers, research labs, and end users is driving breakthroughs that address multifaceted industrial demands. These collaborations enable the rapid prototyping and real-world vetting of new formulations, ensuring faster market introduction and broader acceptance. Industries have co-developed adhesives that do more than bond—they intelligently integrate functions such as structural support, electrical conduction, or heat dissipation within a single adhesive matrix. These hybrid formulations are especially vital for emerging markets, such as electric vehicles, where battery safety and efficiency depend on multifunctional solutions. Collaborative research not only expedites the problem-solving process but also encourages the pooling of intellectual property and best practices, accelerating the industry-wide adoption of revolutionary products. Such collaborative efforts consistently lead to adhesives that directly address evolving real-world challenges by adapting and innovating in step with changing technological landscapes.

Sustainable Solutions

Sustainability concerns are prompting companies to innovate with environmentally responsible adhesive technologies that minimize both environmental impact and embodied energy costs. For instance, biodegradable hydrogels inspired by the unique properties of mussel proteins now deliver bonding strengths triple those of previous ‘bioglues’. Nature-inspired materials offer unique advantages by utilizing the mechanisms perfected by biological organisms over millions of years, resulting in non-toxic adhesives that function in wet, dynamic, or challenging environments. These solutions deliver high performance in critical sectors, such as biomedical devices, while minimizing their environmental impact by being both non-toxic and compostable. These biomimetic advances are already enabling new surgical techniques and eco-friendly medical disposables. They illustrate how cross-disciplinary science is solving long-standing industry pain points while broadening the potential for truly sustainable product life cycles.

Conclusion

Modern industrial adhesives represent a fascinating blend of innovation, collaboration, and sustainability. Lightweight, bio-based, smart, and high-performance formulations are rapidly replacing traditional options in some of the world’s most demanding applications. Today’s adhesives are being called upon to do more than ever before, operating under extreme thermal, mechanical, and environmental pressures. As the industry continues to face stringent consumer, regulatory, and technical pressures, its focus on responsible development and advanced functionality will remain paramount. The commitment to ongoing research and intersectoral cooperation will shape not just the future of adhesives but the global manufacturing landscape as a whole. This ongoing evolution is setting a new standard for adhesives, equipping manufacturers with critical technologies for the next era of industrial progress and reinforcing the foundation of the world’s essential industries.