The discussions around hard hats tend to center on the shell, from its material to its thickness to the level of impact rating it possesses. But the shell is only half the equation. The part that protects your head when impacted is the suspension system, and it’s an element that’s unfortunately been neglected for far too long in safety design considerations.

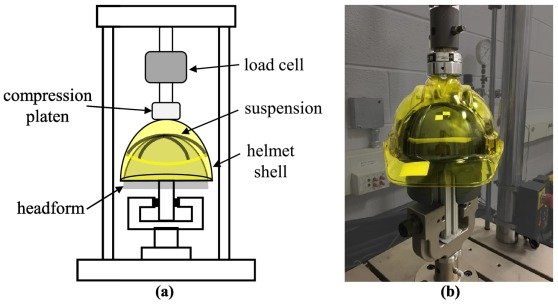

The mechanics haven’t changed much since hard hats became required industrial equipment. A suspension system keeps the shell off your head and creates a comfort zone to absorb impact energy before it gets transmitted to your skull and thus the connective tissues and nerves that control our ability to function. What changes is how effective these systems are at doing that which completely redefines what industrial head protection has to offer.

The Design Flaw

Suspension components were relatively simple back in the day, a simple series of strips connected to the shell with a pin and hole adjustment to pull it tight, pinch it, or leave it sagging. Basically, they kept the helmet off one’s head, mission accomplished. But how did they actually operate during impact forces?

Rigid suspensions might survive a top-down hit okay, but what about an object that strikes the left part of the helmet or a worker who collides with a beam? There are forces that travel differently through systems and they’re not equipped to handle them properly based on old technology.

Additionally, while comfort might seem secondary to impact survivability, it’s actually more integral than one might think. Uncomfortable equipment isn’t worn appropriately. Workers adjust their straps incorrectly, wear their helmets too loosely, or find reasons not to have them on when they need to. A suspension that digs into one’s forehead or has pressure points after three hours of wear becomes a compliance concern, not a nuisance.

What 21st Century Suspension Technology Does

Today’s systems use materials and components that yesterday’s safety could only dream of providing. No more rigid parts but engineered cradles whose purpose operates on multiple points of contact. The materials themselves act differently upon impact, they compress and absorb energy instead of merely transmitting it directly to one’s skull.

The distance does matter, and more than people realize. Too close to the shell and the operating comfort area is lost. Too far and the helmet becomes completely unstable and awkward on one’s head. Advanced suspensions maintain their distance even after impact has struck so that protection is rendered effective throughout an incident instead of collapsing immediately.

Ratchet adjustments over pin and hole systems allow for a proper fit without fighting with the equipment. This may sound trivial until you’ve seen workers try to adjust their helmets while wearing gloves in frigid temperatures. The easier something can be adjusted, the more likely it’ll be worn correctly.

The Lateral Protection Sensation

Impact from above was always a priority, and it makes sense; falling objects are more likely to happen than not. Yet statistics show otherwise, as head injuries occur more frequently from lateral impacts, whether workers colliding with machinery or getting hit by moving objects. Standardized suspensions don’t perform well under such conditions.

Premium helmets began integrating their suspensions for lateral impact considerations. For organizations that operated high-overhead work, confined spaces, or areas of heavy equipment traffic, lateral protection became increasingly necessary. The v-gard suspension geometry represents both vertical protection based on distance maintained from various angles, which is why it’s become standardized in refineries and industrial compartments where impacts occur from all directions.

Testing illustrates the difference too, Type 2 helmets with their superior suspension systems withstood side impacts that would’ve caused serious trauma to workers wearing older versions. This is crucial when working around machinery, demolition spaces, or any area where unanticipated impacts could occur from different angles.

How Weight Distribution Changed Everything

Uncomfortable helmets that have front-heavy designs or want to tip forward every time one bends over create major discomfort beyond annoyance. Workers overcompensate by improperly strapping them down tighter or moving them into positions where proper protective options are rendered void.

Said to be the most comfortable aspect of 21st century systems, advanced suspensions create pressure placement through headband design; wider designs spread pressure across more of one’s forehead and side than creating hot spots that develop into more uncomfortable sustained operations. Some systems use foam padding at contact areas; others rely upon the design itself to minimize pressure accumulation. Regardless, both methods work best when workers never notice them throughout their entire shift in spite of wearing hard hats properly positioned.

Balance exists, too, suspension systems operate best in supported placements when revolved around head movement without feeling awkwardly tight. This means looking up often, working low to the ground, or changing positions frequently, an improperly balanced helmet would shift around instantly.

The Accessory Integration Challenge

The need for more than head protection creates challenges on modern job sites, grinding operations require face shields; high-noise areas require hearing protection; work at heights requires chin straps; specific kinds of facilities require mounted communication systems or headlamps. Each incremental accessory presents integration connections that impact how well a suspension adheres.

Older suspensions weren’t built with accessories in mind; face shields compromised suspension adjustability; mounted hearing protection created pressure areas; chin straps pulled the helmet down in ways where suspensions behaved oddly on one’s head. These aren’t theoretical inconveniences, they were daily operational concerns where workers jerry-rigged solutions that compromised protective capabilities.

Modern integrative solutions contain attachment ports and mounts that allow accessories to be added without compromising positioning over functionality. The geometry of suspensions accommodate excess weight and pulls through accessories to balance everything out, and it makes a difference because workers shouldn’t have to choose between types of protection instead of a jerry-rigged solution that voids their warranty.

What the Performance Data Shows

Controlled testing labs assess performance through standardized impact situations; real-world data shows as much if not more. Facilities that upgraded systems reported less head injuries when types of relevant work remained constant – this is in part due to improved impact protection but compliance increased as well – as workers wore them correctly because they were comfortable enough for prolonged shifts.

Durability shows over time as well – as once old suspension systems showed wear faster losing their capacity for absorption as materials degraded from sweat exposure, UV light and repeated tensions. New-age materials maintain their protective properties longer, even though replacement assessments need consistent attention. A suspension system may look great but lack substantive protective qualities, which is why manufacturers have replacement schedules based on time instead of wear/tear alone.

Making the Transition

Transitioning doesn’t always mean replacing every helmet. Many offer suspension retrofits to bring old shells up-to-date with current performance levels, but only when shells meet requirements as well. For companies with massive inventories of equipment, this helps spread upgrade costs, and time, but ensures improved protective values are in place.

Greater effort is spent in getting buy-in. Workers who’ve had hard hats for years need to understand why new ones function differently, and how adjustments play a key role; poor fitting flouts even the best suspension technology so efforts must be made to ensure everyone knows how to set up their equipment before it can receive buy-in.

Where the Real Good Stuff Was Found Out About Industrial Head Protection

Suspension systems became where all the other innovations happened with real revolutionized protection for heads from falls and strikes. The shell matters, testing capabilities matter, but positioning that shell appropriately on one’s head during an impact, that’s what separates adequate protection from truly valuable safety equipment.

The facilities who figured this out early changed their reported injury numbers before regulations caught up, and there’s a disparity between minimal compliance regulations and actual real protective value which continues widening as suspension technology improves.