Maintaining the integrity of a building’s roof is fundamental to ensuring the structure’s long-term durability. Regular upkeep, including roof restoration and professional roof coatings, helps protect one of the most exposed components of any building from weather, wear, and aging. Embracing strategies such as commercial roofing restoration allows building owners and managers to avoid premature roof replacement, reduce operational costs, and extend the usable lifespan of their assets.

The process of restoring a roof and applying high-performing coatings is a proactive measure to preserve functionality, safeguard occupants, and improve energy use. These methods enhance building performance and, by reducing environmental and financial burdens, prove to be an intelligent investment over the years.

Roof coatings, specifically designed to provide robust protection against the harshest elements, are becoming increasingly popular within the commercial and residential sectors. As more property owners realize their long-term benefits, these coatings are used as preventative measures and solutions for existing roof problems.

Understanding how to maintain and enhance your roof is key to optimal property management. This guide will cover the restoration process, the benefits of specialized coatings, and how these efforts improve durability, efficiency, and sustainability for buildings of all types.

Understanding Roof Restoration

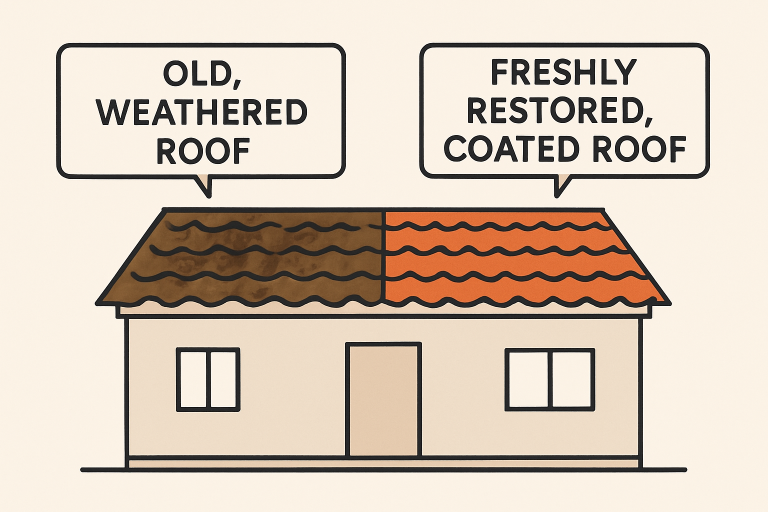

Roof restoration is a process that focuses on reviving and protecting existing roofing systems rather than replacing them. This typically includes a thorough inspection, cleaning, repairs to address leaks or worn areas, and the application of a protective coating. By addressing the underlying issues caused by weather, debris, or age, restoration helps restore an aging roof to an optimal state.

This process is considerably less disruptive and far more affordable than a full roof replacement. Not only does restoration address current damage, but it also provides a renewed waterproof surface and increases the building’s resistance to future environmental stress. For many, it is the sustainable option that maximizes return on investment, especially in large-scale or historic structures. According to Buildings.com, restoration can delay the need for a new roof by a decade or more, saving both money and resources.

Benefits of Roof Coatings

Roof coatings are engineered materials applied over roof surfaces to extend their lifespan and enhance their performance. These coatings offer several key benefits, making them an attractive choice for building owners seeking to protect their properties. First, coatings shield surfaces against UV rays, rain, and wind, delaying the breakdown of membranes and roofing materials. This can add up to 15 years to the roof’s life. Other benefits include:

- Leak Prevention: Coatings create a uniform membrane over the roof, efficiently sealing small cracks and seams to prevent water intrusion.

- Energy Efficiency: Most coatings have highly reflective properties, which reduce heat absorption in the building, cutting cooling costs.

- Low Maintenance: Coated roofs require less regular upkeep, as the surface is easier to clean and less susceptible to minor damage.

As an added bonus, coatings can enhance the aesthetics of an aging roof, creating a cohesive appearance and increasing property value.

Types of Roof Coatings

Several types of roof coatings are available, each with specific characteristics suited to different climates and roof types. Understanding these options helps property owners select the best solution for their needs:

- Acrylic: Water-based acrylic coatings are highly reflective and cost-effective. They are widely used in moderate climates due to their ease of application and environmental friendliness.

- Silicone: Silicone coatings excel in environments with frequent rain or standing water, as they form a moisture-tolerant barrier. Their superior UV resistance helps prevent yellowing and degradation caused by sunlight.

- Polyurethane: These coatings are known for their outstanding durability and resistance to physical impact, making them suitable for roofs that see heavy foot traffic or equipment usage.

Each type has its strengths and best use cases, so professional guidance is essential for achieving the desired protection and durability.

Energy Efficiency and Cost Savings

One of the most compelling reasons to apply reflective roof coatings is their significant effect on a building’s energy performance. Coatings with high solar reflectance can lower roof surface temperatures by as much as 50 percent in peak summer months, leading to 10 to 40 percent reductions in cooling costs. The Department of Energy notes that cool roofing solutions can substantially reduce a facility’s air conditioning requirements, making them an excellent choice for commercial and residential buildings in warm regions.

For single-story facilities and buildings with substantial roof exposure, the financial upside is especially strong. By integrating cool coatings, owners reduce HVAC strain, save on repairs, and achieve long-term savings on energy bills.

Environmental Impact

Roof restoration and coatings are environmentally friendly solutions that minimize waste and reduce resource consumption. Rather than discarding old roofing materials into landfills, restoration and recoating keep the existing structure in place, reducing debris and raw material use. Additionally, the reflective properties of modern coatings help counteract the urban heat island effect, improving local air quality and reducing carbon emissions. These sustainable practices align with green building certifications and local government initiatives to improve energy efficiency.

Maintenance and Inspection

To ensure maximum lifespan and performance, regular roof inspections and proactive maintenance are critical. Building professionals recommend inspections at least twice a year to spot potential issues early and address minor concerns before they develop into larger, costly repairs. Preventive maintenance protects the roof from premature deterioration, preserves warranty coverage, and assures building safety for occupants.

Choosing the Right Professional

Partnering with a highly qualified roofing contractor makes a significant difference in the results achieved through roof restoration and coatings. It is important to work with professionals who are incredibly well-versed in roof materials and coating systems, hold the proper certifications, and maintain a solid reputation for quality and reliability. A detailed onsite evaluation, transparent proposals, and verifiable references are good indicators of a reputable provider. Engaging the right expert ensures tailored recommendations and long-lasting performance for your building envelope.

Investing in roof restoration and coating technologies is one of the most effective ways to increase building longevity, improve energy efficiency, and reduce operational costs. Combined with routine maintenance and guidance from industry professionals, these interventions deliver value far beyond their initial cost and are a wise choice for sustainable property management.