Precision in chemical blending has become increasingly critical across various industries, including pharmaceuticals, coatings, and specialty chemicals. As formulations become more complex, achieving consistent quality and accurate proportions requires advanced methods that surpass traditional mixing techniques. Modern approaches focus on optimizing reaction efficiency, minimizing errors, and maintaining product stability, all while adhering to rigorous safety and environmental standards. Innovations in this field are enabling manufacturers to meet demanding specifications with greater confidence and repeatability.

Central to these advancements is the industrial mixer for chemicals, which enables the controlled and uniform blending of multiple components. By providing precise control over speed, shear, and temperature, these mixers help reduce variability and enhance the consistency of end products. As industries continue to evolve, adopting such precision techniques ensures that chemical processes remain efficient, reliable, and adaptable to increasingly sophisticated formulations.

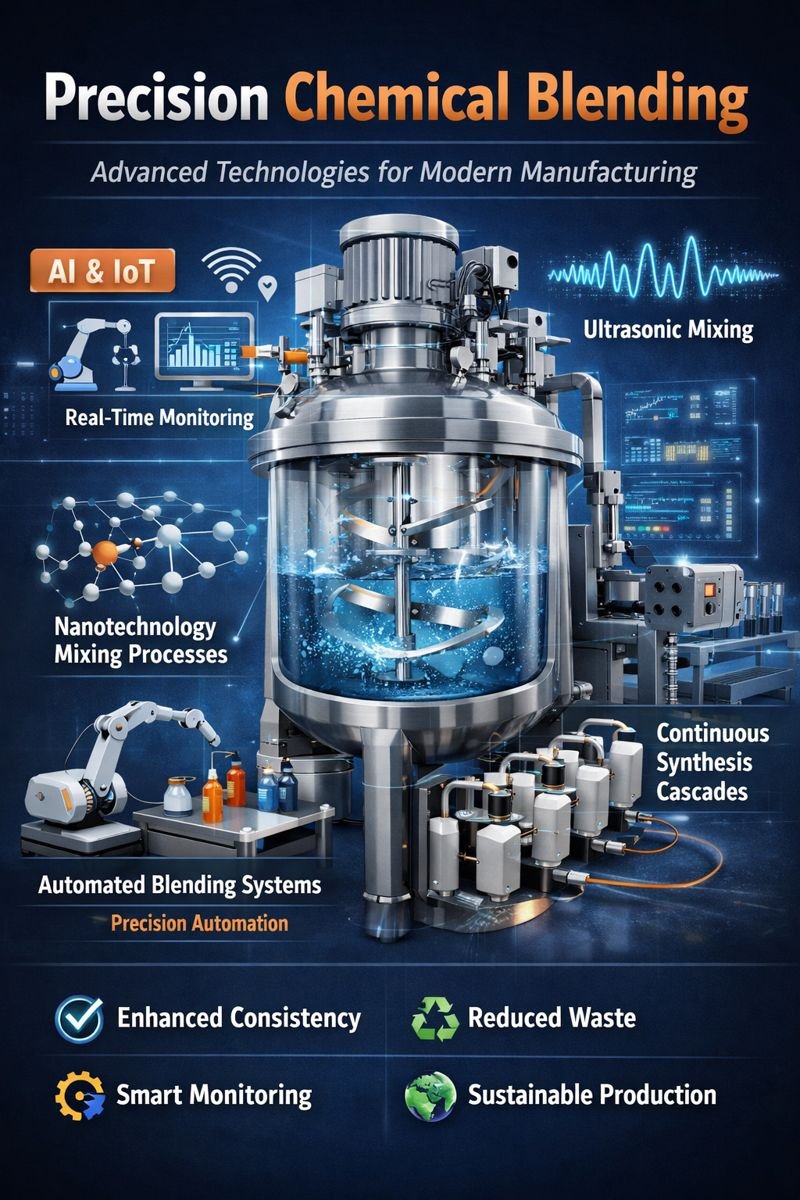

Advanced Mixing Technologies

The development of mixing technology has led to advanced designs and mechanisms that optimize turbulence and dispersal of ingredients. Modern industrial mixers provide controllable and consistent performance for a wide range of materials, including those that are fragile. Innovations such as variable-pitch blades or dynamic impellers boost shear and mixing speed, effectively managing different viscosities and densities, which helps prevent stratification and incomplete mixing. Future-ready mixers also feature enhanced cleaning capabilities, reducing turnaround time and supporting continuous operation and sanitation requirements.

Integration of AI and IoT

The integration of AI and IoT has ushered in a new phase in smart chemical mixing, where interconnected sensors and control systems enable real-time monitoring and adjustments. This enables operators to quickly address any changes in blend ratios, temperature, or pressure, maintaining consistent quality. Machine learning analyzes large datasets to forecast maintenance needs, identify anomalies, and refine process settings, thereby reducing downtime, boosting throughput, and cutting material and energy consumption. As a result, products become more uniform, equipment failures decrease, and operational disruptions lessen. Furthermore, the integration of AI and IoT across multiple sites standardizes procedures globally, thereby supporting regulatory compliance.

Nanotechnology in Blending Processes

Nanotechnology has revolutionized industries that require extremely fine particle sizing. At the nanoscale, the surface area-to-volume ratio increases dramatically, making precise particle blending essential for optimal performance, stability, and safety. Nanoscale mixers disrupt agglomerates to ensure even dispersion, often reducing ingredient quantities while achieving equal or superior results compared to coarser blends. This level of precision is especially crucial in pharmaceuticals, where the uniform dispersion of components significantly impacts drug efficacy, consistent bioavailability, and controlled release. The benefits extend to coatings, adhesives, and high-performance materials. Additionally, nanotechnology enables the development of new formulations that were previously impossible with traditional methods, fostering innovation across various markets.

Continuous Synthesis Cascades

Traditional batch processing can be labor-intensive and inefficient, as it requires different equipment, cleanouts, and setups for each stage. This leads to bottlenecks, contamination risks, and excess intermediate waste. In contrast, emerging continuous synthesis cascades combine multiple reactions and blending steps into a seamless process, boosting throughput and sustainability. Flow chemistry and modular plant designs offer immediate advantages, including faster production cycles and improved reproducibility of complex formulations. Using a single reactor for multiple synthesis and blending steps reduces energy consumption, lessens retooling time, minimizes waste, and enhances product quality. These systems also support flexible manufacturing, enabling quick adjustments to market demands with minimal disruption.

Automated Blending Systems

Automation has revolutionized chemical blending through PLCs, real-time monitoring, and inline dosing, enabling precise ingredient control. Current systems incorporate recipe software that is connected to plant controls, minimizing operator errors and ensuring accurate batch tracking. Automated blending provides consistent, safe, and repeatable outcomes, particularly when handling hazardous substances. Inline units operate continuously, eliminating downtime and facilitating rapid adjustments to formulas or capacity. Sensors monitor ingredient consumption, notify teams for replenishment, and improve productivity and traceability for quality audits.

Mixing Intensification

Advanced mixing methods, such as ultrasonic and electric-field-assisted agitation, introduce additional physical forces to enhance or replace traditional stirring. These techniques create energetic micro-environments that enable quick dispersion and speed up slow reactions. They also enhance mixture uniformity and consume less energy compared to standard methods. For example, ultrasonic mixing disperses nanoparticles and accelerates reactions, enabling the production of high-performance materials and specialized products. Overall, these technologies support sustainable manufacturing by reducing energy consumption and lowering the chemical industry’s carbon footprint.

Conclusion

Embracing new techniques in precision chemical blending is essential for industries that prioritize consistent quality, operational efficiency, and sustainability. Companies that invest in advanced equipment, smart automation, and cutting-edge science gain a measurable advantage in an evolving landscape marked by rapid technological progress and growing regulatory demands. Harnessing innovative tools and digital solutions not only benefits the bottom line but also ensures compliance with ever-tightening product and environmental standards. Continuous improvement and willingness to adopt breakthroughs in chemical blending will remain pivotal in shaping the future of manufacturing for years to come.