Concrete has long stood as the backbone of the built environment, but today’s construction sector is witnessing a profound evolution in how this vital material is used. With forward-looking advancements making their way into residential and commercial projects, the industry is rapidly adapting to new standards of efficiency, design flexibility, and environmental responsibility. Whether you’re a homeowner planning a remodel or a developer breaking ground on a new build, choosing the right concrete contractor is essential in leveraging these innovative trends. The newest techniques deliver more appealing results and redefine durability, resource management, and smart integration. These advances mark an era where concrete is key to architectural expression and sustainability. From innovative fabrication to data-driven solutions improving building stages, the future of concrete services is brighter, smarter, and more eco-friendly. Embracing these trends helps property owners maximize value and performance, creating spaces that are both durable and inspiring.

3D Printing in Concrete Construction

3D printing has emerged as a transformative force within concrete construction, dramatically reshaping what’s feasible in design and execution. Unlike traditional casting methods, 3D printing enables the formation of complex architectural features and intricate elements directly from digital models. This approach allows for greater design variability—consider stunning facades, bespoke structural pieces, or even futuristic furniture—and significantly minimizes material waste and time spent on site. Industry leaders are already applying this technology in residential and commercial contexts, with notable examples including custom pavilions and structural components that would be impossible or prohibitively expensive to construct by hand.

Smart Concrete Technologies

Concrete is evolving into an intelligent material integrating embedded sensor networks and advanced admixtures. Smart concrete systems allow for proactive condition monitoring through sensors embedded during pouring, tracking everything from moisture content to strain and crack formation. This real-time feedback supports predictive maintenance, potentially preventing costly repairs and improving safety by swiftly identifying structural vulnerabilities. By leveraging such smart materials, property owners and facility managers gain unprecedented insight, reducing lifecycle costs while extending the durability and reliability of their assets.

Sustainable Concrete Solutions

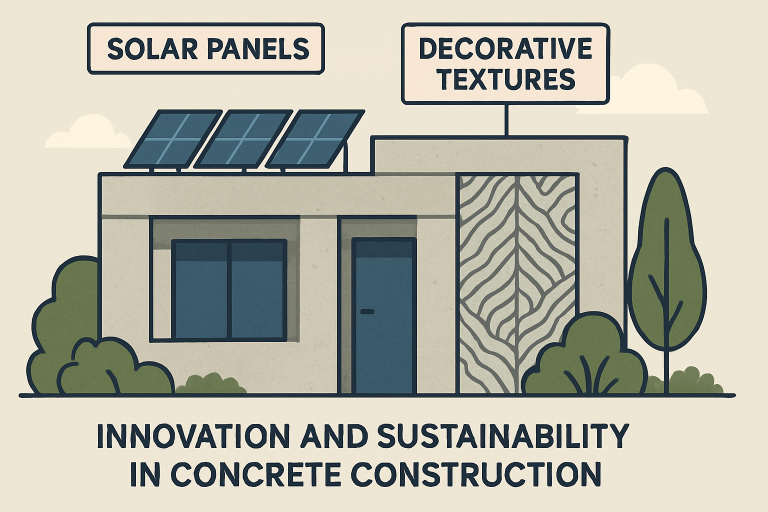

Environmental consciousness is at the forefront of today’s construction mindset, and concrete is no exception. The industry is adopting more sustainable practices—from incorporating recycled aggregates to using low-carbon cement alternatives and supplementary cementitious materials. Innovations such as carbon-capturing mixes, geopolymer concretes, and energy-efficient curing processes are enabling significant reductions in the carbon footprint of both residential and commercial buildings. Adopting these solutions ensures structures are environmentally responsible without compromising quality or longevity, making sustainability a key differentiator in the concrete sector.

Decorative and Customizable Finishes

Concrete’s versatility is celebrated like never before, with new decorative and customizable finishes bringing visual flair to interiors and exteriors. Stamped concrete replicates the authentic look of brick, stone, or even wood for patios and driveways, while polished and stained finishes offer vibrant, contemporary aesthetics for floors and countertops. Customizable colors, textures, and embedded graphics enable nearly limitless design expression, making concrete a preferred choice for creative architects and discerning homeowners. Thanks to these options, contractors can deliver surfaces that look as distinguished as they are durable, supporting branding for businesses and unique style statements for residential properties.

Precast and Modular Construction

Speed and precision are more important than ever in today’s fast-paced construction world, and precast or modular concrete methods are answering the call. By manufacturing concrete elements in a controlled factory environment and then delivering them ready for assembly, companies reduce exposure to weather delays, maintain consistency, and cut labor costs. This shift supports quicker project turnovers, which is particularly valuable for commercial developments or multi-unit housing projects where timelines are crucial. Moreover, modular systems allow for easier expansion and adaptability, future-proofing buildings for evolving needs.

In many precast and modular projects, the ability to move and place concrete and grout with consistent pressure and minimal downtime is as important as the elements themselves. Equipment choices that match factory-controlled pours and rapid on-site assembly can reduce cycle times and improve joint quality; selecting the right pump can streamline placement for grouts and form fills. Manufacturers now offer a full line of s-tube and ball valve pumps suited to both precast production and fast-track modular assembly, designed for durability and precise material control. Specifying pumps that are easy to maintain and available through global distribution helps keep factory schedules and just-in-time deliveries on track.

Data-Driven Project Management

Incorporating smart tools and analytics is taking project management in the concrete industry to new heights. Wearable devices, connected sensors, and project management software are streamlining every stage, from procurement to installation. With better visibility into project data, contractors and stakeholders make informed decisions that help reduce waste, prevent overruns, and optimize resource allocation. Transparency and accountability improve, as digital records track everything from weather impacts to material usage—resulting in smoother builds and higher-quality outcomes.

High-Performance and Lightweight Concrete

Concrete chemistry advancements are leading to stronger and lighter formulations, offering tangible benefits for challenging builds. High-performance concrete (HPC) boasts remarkable compressive strength, enhanced resistance to harsh environments, and durability tailored for bridges, tunnels, or high-rise towers. Lightweight concrete varieties, utilizing expanded aggregates or foamed mixtures, reduce a building’s structural load while maintaining integrity. These options are pivotal in meeting design and engineering criteria, especially where weight savings or extreme resilience is essential in commercial and infrastructure projects.

Conclusion

From digital fabrication and intelligent sensors to eco-friendly materials and design-centric finishes, the concrete industry is navigating a remarkable transformation era. By adopting these forward-thinking trends, homeowners and businesses unlock new levels of efficiency, sustainability, and visual impact in their properties. Staying current with these innovations ensures every project benefits from the best in modern concrete technology, delivering results that endure and inspire for generations to come.